There are 2 ways to produce sandwich panels in PUR / PIR foam, in this chapter, we will identify the advantages of using continuous technology compared to the simpler discontinuous one.

This last system, in fact, now abandoned by the main world producers, is suitable for small productions only, or for panels designed with particular shapes (curved for example).

Obviously it requires a lower economic investment as the cost of the production plants is significantly lower, but this system, compared to the continuous line is less productive and requires more attention in the control of the foaming method which is not always reliable especially in the manual injection version which is the most common.

The continuous line has higher investment costs, but it becomes an indispensable choice when quality and large production volumes are sought.

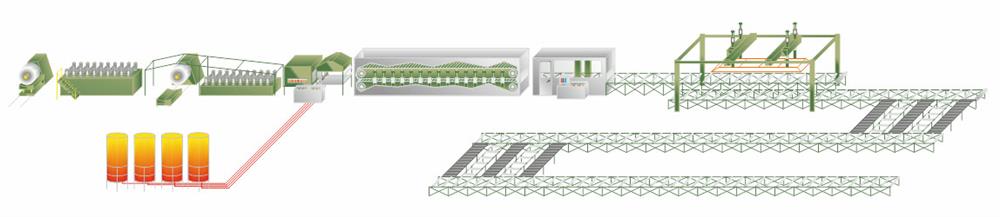

The line is divided into different stations for the processing phases: starting from the reels for the sheet metal, passing in the important phase to the supports pre-heating furnaces - which favor the adhesion of the foam to the metal supports - arriving at the mixing plants of the chemical compounds and foam injection with automated, continuous and uniform method.

The choice of the continuous line is an obligatory choice for companies that invest in technology, reliability and quality, precisely for this reason the panels of Sitav Costruzioni Generali - Isotecnica - are made in this way.